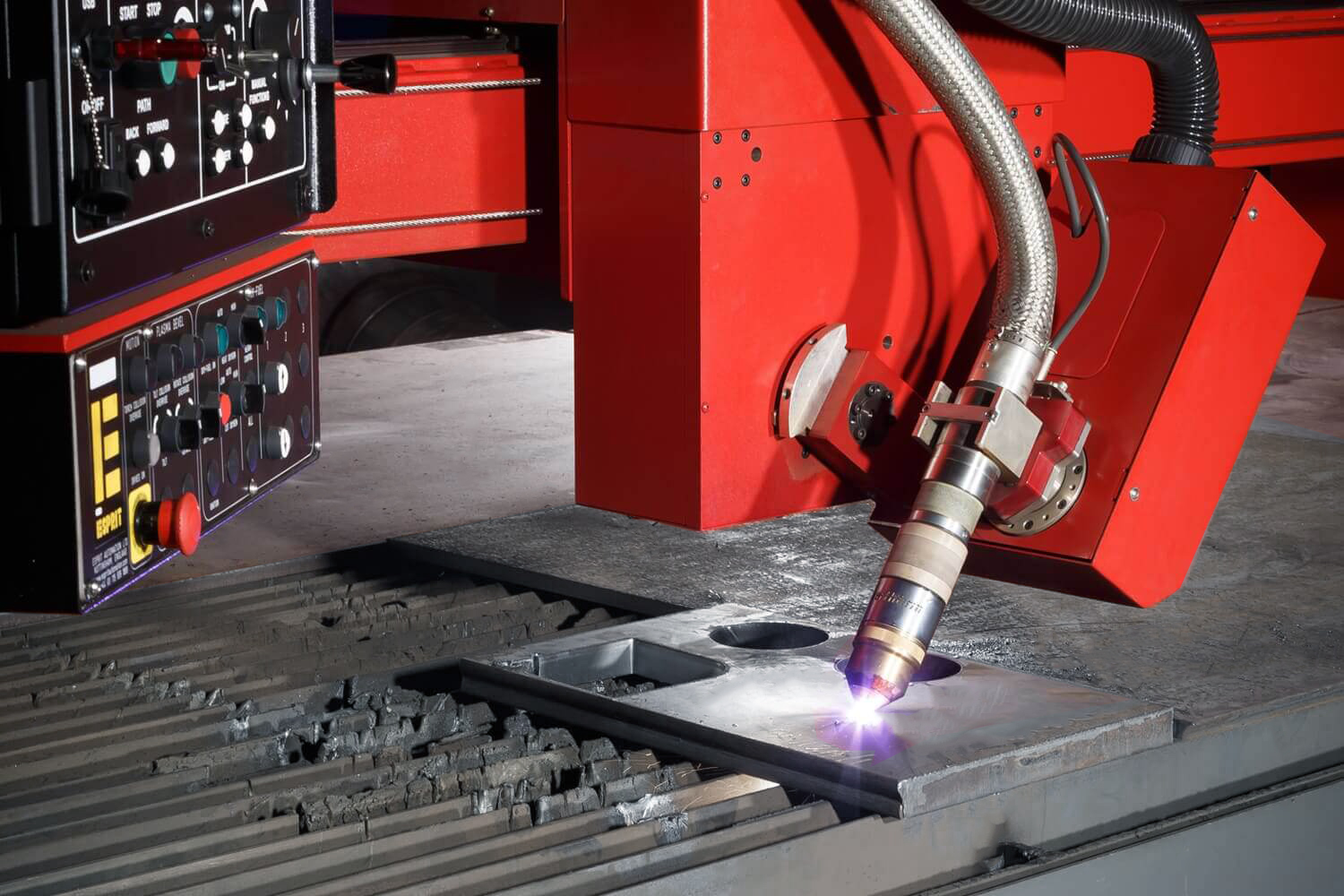

At WECJet, we offer advanced high definition plasma cutting services for stainless steel, mild/carbon steel, and aluminium components. Using the latest Multi Bevel High Definition Plasma Cutting technology, we can accurately cut profiles up to 10 metres long, 2.5 metres wide, and 50mm thick, with a bevel cutting capability of up to ±50° – ideal for weld preparation and complex geometries.

Our dedicated plasma cutting division, WEC Plasma, has been established to enhance our in-house fabrication capabilities and expand our subcontract cutting services for heavy-duty and thick metal profiles.