UK's Largest Engineering & Fabrication Company

WEC Group is one of the largest fabrication and contract manufacturing companies in the UK. The company has over 950 staff and 740,000 sq. ft. of manufacturing floorspace. Its 12 UK manufacturing sites are located across Lancashire, Merseyside, Yorkshire, Dorset, and the West Midlands.

History

WEC Group began as a two-person operation in Darwen, Lancashire, in 1979. Over the past 45+ years, the company has grown steadily year on year. This growth is thanks to skills, dedication, engineering excellence, and ongoing investment in cutting-edge technology. Today, WEC Group is one of Europe’s largest fabrication, contract manufacturing and profiling companies.

Our Values

At WEC Group, our values define who we are and how we work. We are committed to Integrity, operating ethically and honestly. We value Excellence and always strive to exceed expectations. We promote Positivity by creating a supportive and enthusiastic learning environment.

Teamwork is key to driving innovation and morale. We also prioritise Safety to maintain a secure, high-performing workplace for everyone. These core principles guide our apprentices, staff, and daily operations.

Why WEC Group?

At WEC we offer a full in-house manufacturing service from concept, through to design, fabrication & installation. Our specialist team of experts are on hand to ensure the finished product is exactly right.

950

Highly skilled staff

45

Years in Business

740000

sq.ft Manufacturing Floorspace

15

Specialist Divisions

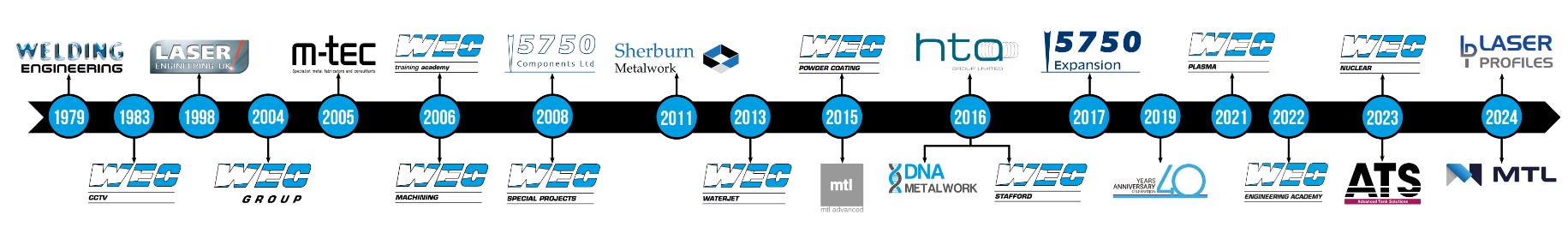

Timeline

Our history timeline highlights WEC Group’s continued growth, showcasing key milestones, acquisitions, and the introduction of new divisions that have shaped us into one of the UK’s leading fabrication and contract manufacturing companies.

Our Facilities

At WEC Group, our values define who we are and how we work. We are committed to Integrity — operating ethically and honestly. We value Excellence and always strive to exceed expectations. We promote Positivity by creating a supportive and enthusiastic learning environment.

Teamwork is key to driving innovation and morale. We also prioritise Safety to maintain a secure, high-performing workplace for everyone. These core principles guide our apprentices, staff, and daily operations.

Group Services

WEC Group delivers comprehensive contract manufacturing services, including advanced fabrication, profiling (laser, waterjet, plasma), precision CNC machining and heavy machining. Our capabilities encompass small to large-scale fabrications, supported by 30-tonne craneage, and extend to specialised services like robotic welding, powder coating, and wet painting.

Our Divisions

WEC Laser, formerly Laser Engineering, was established in 1998 when WEC Group invested in its first laser cutting machine to support a growing fabrication operation and capitalise on emerging technological advancements. As demand quickly exceeded capacity, a second machine was acquired, enabling the company to offer sub-contract laser cutting services. Recognising the industry’s ever-evolving technological needs, WEC Laser has consistently invested in cutting-edge laser cutting technology. Since 2020, WEC Group has allocated over £20 million to capital equipment and additional manufacturing facilities, including state-of-the-art automated 24kw fibre laser cutting technology and 3D fibre tube laser capabilities

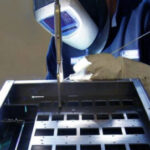

WEC Fabrication is a leading division of WEC Group, providing a wide range of services including laser cutting, CNC machining, coded TIG, MIG and ARC welding, sheet metalwork, large-scale fabrication and assembly. WEC Fabrication supports sectors such as aerospace, construction, defence, nuclear, and marine. Operating from state-of-the-art facilities with craneage up to 30 tonnes and advanced equipment including robotic welding, we handle everything from small precision parts to large industrial fabrications. With over 150 skilled welders and certifications to ISO 9001:2015, EN 1090-1, and ISO 3834, we ensure full quality assurance and material traceability.

WEC Plasma delivers high-quality plasma cutting services for a wide range of materials, including stainless steel, mild steel, carbon steel, and aluminium, with cutting capabilities of up to 10m x 2.5m x 50mm. Utilising the latest Multi Bevel High Definition plasma cutting technology, we produce accurate, clean-cut components suitable for industries requiring both speed and precision, such as construction, general engineering, and heavy fabrication.

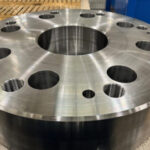

WEC Machining offers a wide range of subcontract multi-axis CNC machining and precision engineering services from our purpose built 33,000 sq. ft. facility. Our highly skilled division based in Blackburn, has the machining capacity of up to 8000mm x 1500mm x 2000mm, as well as being accredited to Aerospace AS 9100 REV C for CC and conventional machining, turning and milling. We have also been involved in the manufacture of quality workshop, industrial and educational machinery.

WEC Large Machining provides post fabrication machining operations to a broad range of industries including niche sectors that require specialist, high accuracy and quality parts such as Nuclear, Aerospace, Oil & Gas and Marine. Based in Darwen, Lancashire, we offer impressive large machining facilities of up to 12.5m x 5m x 3m and are able to carry out entire projects in-house, taking them right through from the initial consultation to the machining and inspection of the completed product.

WEC CCTV is a leading UK manufacturer of camera mounting solutions, supplying a wide range of CCTV poles, towers, columns outdoor cabinets, brackets, and accessories for the security, highways, and commercial sectors. Our product range includes everything from fixed and tilt-over tubular columns to wall and corner poles, cabinet-based trolley poles, and highway structures such as HSTP Square Trolley Poles, Cantilever Poles, and Gantry Mounts.

WEC Rail focuses solely on the design and fabrication of rail Structures such as Signal Gantries, OLE Main Steel & Small Part Steel, and trackside camera mounting structures. We also offer Rolling Stock Metalwork services including EN 15085 accredited Fabrication of Rail components and sub assemblies (Class 1-4). Over the past few years, WEC Rail has experienced a huge increase in demand for its specialist services and now lays claim to many of the rail structures across England and Wales.

WEC Powder Coating delivers high-quality powder coating services nationwide, operating from a state-of-the-art facility in-house. The advanced Gema powder coating system features two automatic reciprocators and a 90% powder recovery system, ensuring efficiency and sustainability. Our facility also includes a 5-stage in-line pre-treatment plant, allowing us to provide durable, corrosion-resistant finishes suitable for even the most demanding environments.